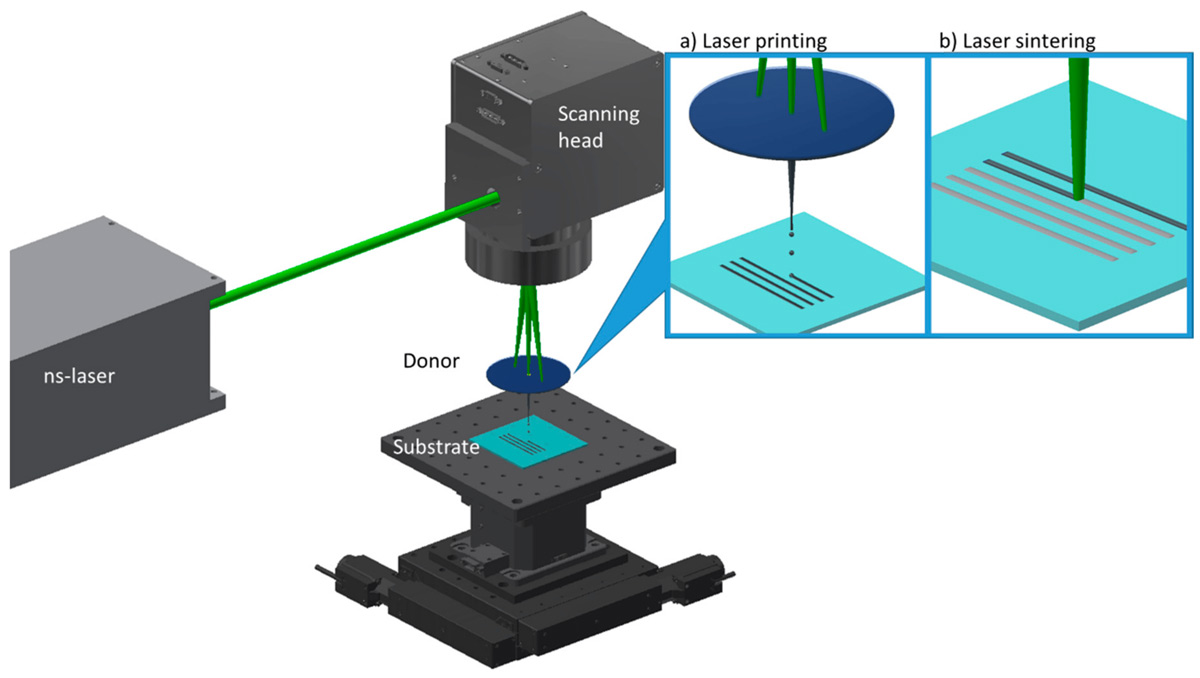

The laser induced forward transfer and sintering of metal nanoparticle inks has been proven a key enabling technology for flexible electronics. Nevertheless, many challenges concerning the conformal processing of non-planar substrates incorporating thermally sensitive layers are yet to be addressed. In this work, we study the behaviour of conformal laser printing of silver nanoparticle inks on patterned samples comprising sensitive underlying structures, by correlating the laser sintering powers employed to the undesired effects on the adjacent interfaces. The latter include demanding surface topographies with periodic patterns and micro-components exhibiting aspect ratio in the nano to 100-micron scale. We investigate the contribution of crucial processing parameters, such as the per pulse energy, repetition rate and the pulse to pulse spatial and temporal overlap to the overall result. The demonstrated results validate the versatility of laser processing which can offer application specific solutions on different use cases involving multilayered and multimaterial electronics.

8 Hamasger st.

P.O. Box 236

Migdal Ha’Emek, 2310102 Israel

P.O. Box 236

Migdal Ha’Emek, 2310102 Israel

Phone: +972-4-6546881

Fax:+972-4-6546880

Fax:+972-4-6546880

Key Sicrys™ Patents Granted:

USA US 9556350, 10166602, 10984920, 11590567

Russia RU 2593311, 2730285

China CN 103282969

Japan JP 6067573 & JP 6363138

Europe EP 3113897, EP2649621

Israel IL 226665, IL247528

Copper WO PCT/1B2015/051536 (WO2015132719)

Silver WO PCT/US2011/063459 (WO2012078590)

SicrysTM Pending Patent: Nanometric SINGLE-CRYSTAL SILVER Pastes GB2414384.4

USA US 9556350, 10166602, 10984920, 11590567

Russia RU 2593311, 2730285

China CN 103282969

Japan JP 6067573 & JP 6363138

Europe EP 3113897, EP2649621

Israel IL 226665, IL247528

Copper WO PCT/1B2015/051536 (WO2015132719)

Silver WO PCT/US2011/063459 (WO2012078590)

SicrysTM Pending Patent: Nanometric SINGLE-CRYSTAL SILVER Pastes GB2414384.4